Glass & Lead Refractories

Glass Refractories

Prime Alloys offers a technologically advanced and comprehensive refractory portfolio for the flat glass, container glass, and speciality glass segments. TRL Krosaki’s product and service range includes unshaped (monolithic) refractories and ceramically bonded bricks, engineered for use throughout the glass melting process across various glass types.

For all glass industry furnaces, our silica, alumina–silica, alumina, zircon, and chrome-containing high-performance refractories are designed to meet stringent customer requirements, delivering thermal stability, corrosion resistance, and long campaign life.

TRLK’s branded products include:

- TRL HIAL 60

- TRL 42D

- TRL ZRM

Lead Refractories

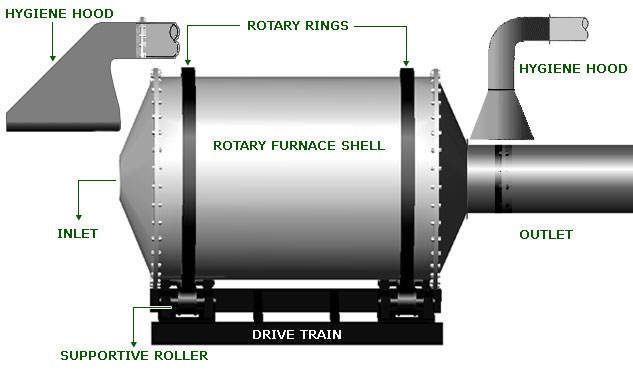

Reverberatory and rotary furnaces are widely used in lead smelting and refining operations, where heat reflected from the arched roof and furnace walls is utilized to melt and purify lead from scrap or oxide ores.

The presence of PbO in these processes necessitates the use of refractories with specialized porosity characteristics and very low SiO₂ content to prevent the formation of low-melting-point eutectics. Accordingly, our refractory solutions offer:

- Low porosity

- High chemical resistance

- High abrasion resistance

TRLK’s branded products include:

- TRL LC90

- TRL 80 BC

- TRL 70 LRF

Our glass and lead refractory solutions are engineered to perform reliably under chemically aggressive and high-temperature operating conditions, ensuring process stability and extended service life.